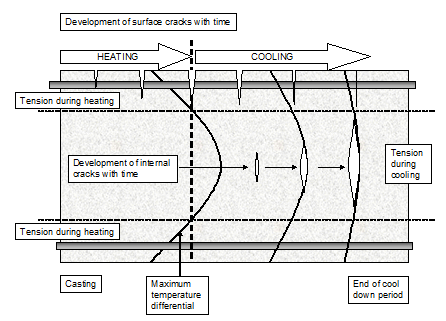

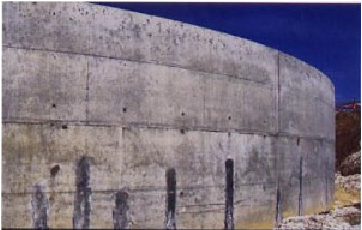

Thermal cracking in the structural concrete of foundations, bridges, tunnel linings, nuclear and water retaining structures has become an increasing problem in the past decades. Controlling the early age temperature of concrete is considered as an important parameter in both in-situ and precast applications for serviceability and ultimate limit state issues since heat of hydration during curing has been established as the main cause of restraint stresses leading to cracks in both reinforced and unreinforced concrete. Shrinkage and thermal stresses that induce cracks in concrete structures occur respectively due to shrinkage effects and temperature difference in concrete’s core and surface.

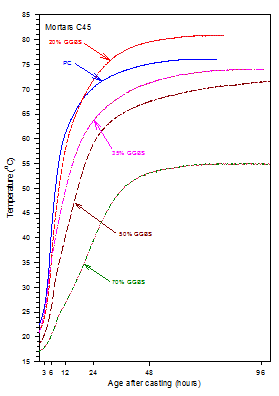

The temperature differentials and thermal gradients, which are considered to be responsible for stress concentrations which result in thermal cracking could be minimized by addition of Ground Granulated Blastfurnace Slag (GGBS), however, it was found that the tensile strain capacity of concrete with 70 per cent of GGBS at an early age is lower than that of the Portland cement concrete and that with sections over 2.5m deep the reduced tensile strain capacity of the GGBS concrete may cancel out the benefit of the reduced temperature rise. The aforementioned indicates that the use of GGBS should not be based solely on its ability to reduce the heat of hydration and develops a controversy on whether partial replacement of Portland cement with GGBS is effective or not in mitigating thermal cracking. Furthermore design guidance for engineers currently depends entirely on Eurocode EN1992 where there are fears that EC2 design considerations fail to properly tackle early-age thermal crack control and could lead to insufficiently robust design solutions.

A major part of the construction schedule and of the development of safe and durable structures relies on appropriate curing and temperature and strength development of concrete elements. It is, therefore, crucial to be able to accurately predict the temperature rise and strength development in concrete in order to take advantage of its high early age temperature rise without damaging it at early stages or diminishing its later age performance as temperature and strength development are directly related with critical operations such as formwork striking times, removal of props, prestressing and post-tensioning, lifting and transportation of precast units. At the same time, controlling/reducing the temperature and heat output of concrete potentially by partially replacing cement with GGBS and/or by providing enhanced design considerations for reinforcement detailing could result in thermal cracking mitigation.

Moreover the incorporation of GGBS as a cement replacement material not only leads to more economical concretes but also to sustainable and environment friendly concrete. As it has been reported, currently the UK uses 2 million tonnes of GGBS as a cement replacement material every year, saving over 2 million tonnes of carbon dioxide emissions. However, limited knowledge exists on the effects of GGBS in the thermal and generally early age mechanical properties of concrete. Furthermore, the project includes work with ready mix and precasting companies which will benefit from the outcome of the project as techniques to monitor and predict the strength and temperature development in structural elements will be developed. Civil engineering industrial organisations concerned with the construction of reinforced and unreinforced concrete together with the owners of bridges, tunnels, concrete dams and nuclear power stations will also benefit from the better engineered structures.

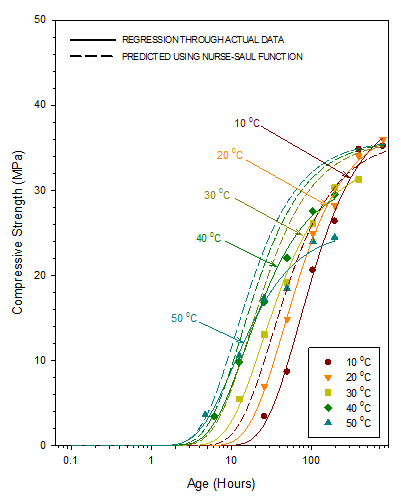

Admittedly, due to the amount and significance of the parameters that affect concrete’s behaviour, mechanical properties and performance , concrete is a very complex material to model and interpret and its level of complexity increases when supplementary cementitious materials, such as GGBS, are incorporated. The incorporation of supplementary cementitious materials in concrete mixes, such as GGBS, seem to reduce/control the high early age temperature rise in concrete but they also have significant effects on its thermal and ,generally, early-age properties which simultaneously vary with time and temperature, where limited knowledge exists. The numerical techniques that have been developed to predict the heat problem and strength development in concrete, such as the temperature-time factor known as the maturity method, do not yet produce adequate results due to its complexity, stressing the need for development of improved techniques that can give better and more accurate predictions.

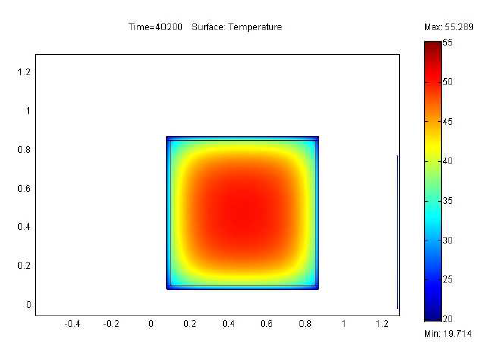

Modelling of reinforced concrete induced with thermal stresses is a very complex and challenging problem itself and will produce an integrated image of how stresses and cracks occur and propagate in concrete, what is the actual contribution of the reinforcement in restraining concrete’s tendency to move and eventually crack, how the existing design guidelines address this issue and whether there is potential for additional improvements on reinforcement detailing and design considerations.