What is a geopolymer concrete?

A geopolymer is a synthesised inorganic material that has been used in a wide range of diverse applications such as heat-resistant ceramics, waste encapsulation and construction products over the past 40 years. Our Geopolymer Team in Queen’s University Belfast is currently examining the potential use of geopolymer materials to create new types of geopolymer concrete.

Why geopolymer concrete?

Concrete is one of the most common building materials used in the construction of buildings, bridges and infrastructure across the world. Whilst concrete is an excellent construction material it’s manufacture releases a large amount of carbon dioxide (CO2) .

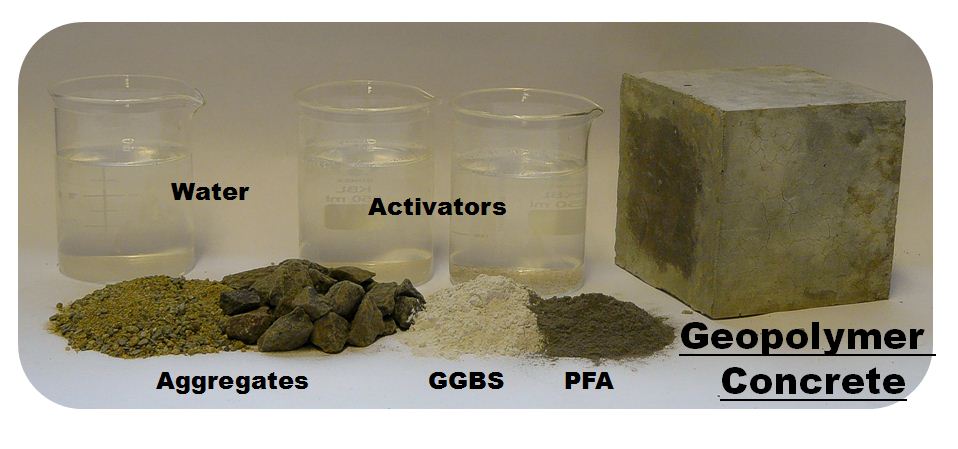

The major constituents of conventional concrete by volume is coarse and fine aggregates, typically natural quarried stone or sand. The aggregates are formed into a concrete matrix following the addition of water and a binder such as Ordinary Portland Cement (OPC). The quantities of each constituent may be varied to achieve different desirable criteria such as high strength, workability and durability.

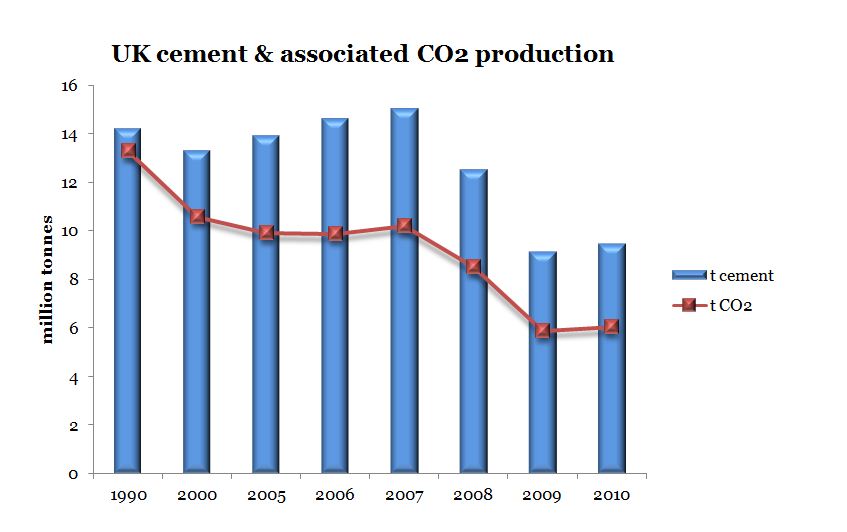

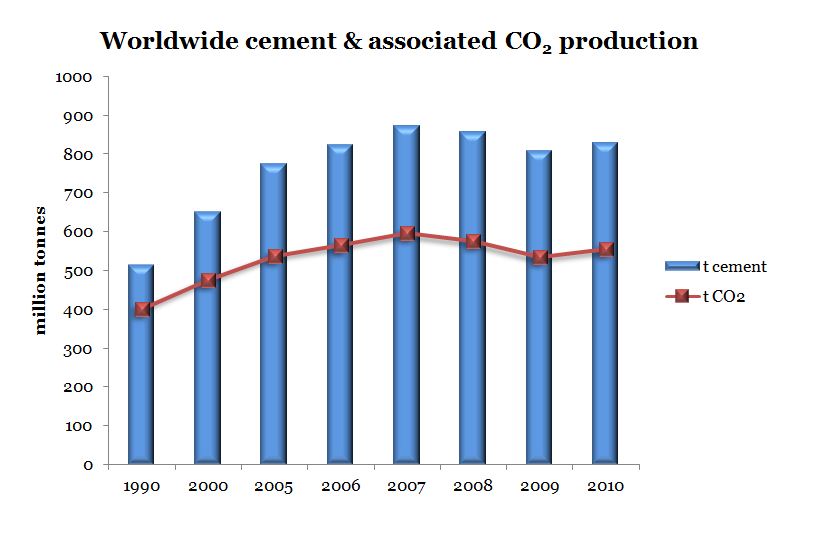

The production of OPC binder has already been recognised as source of significant environmental damage as source of between 5-8% of anthropogenic CO2 emissions worldwide. The World Business Council of Sustainable Development launched the Cement Sustainability Initiative Getting the Numbers Right which has recorded the worldwide production of cement and associated CO2 since 1990.

In the UK there has been a reduction of the amount of CO2 produced per tonne of cement as the industry improves the efficiency of the manufacturing process and opts to increase the amount of low-carbon/carbon-neutral fuel sources to power cement kilns. Whilst these reductions are promising there is a limit of how much further the CO2 produced per tonne of cement can be lowered. OPC is manufactured by heating limestone which brings about the decomposition of the calcium carbonate (CaCO3) to form to quicklime (CaO) and carbon dioxide (CO2). The CO2 release from this heating process, referred to as calcination accounts for approximately 50% of the total CO2 emitted during cement manufacture.

In order to reduce further the CO2 emissions associated with concrete further viable alternatives to replace OPC are being examined with geopolymer materials considered to be one such alternative.

Geopolymer definition

Given the large number of potential applications for geopolymer materials it’s definition is continually evolving. The most recent definition of geopolymer materials was presented by Prof. Joseph Davidovits, the founder of The Geopolymer Institute, at the GeopolymerCamp 2012 and is summarised below.

- X-ray amphorus at low temperature.

- Crystalline at tempteratures exceeding 500C.

There are two potential synthesis routes:

- Alkaline activation by sodium (Na), potassium (K) & calcium (Ca).

- Acidic activation by phosphoric acid.

Benefits of geopolymer

Geopolymer concretes offer a number of benefits over conventional OPC concrete including:

- significantly lower CO2 emissions than OPC concretes – up to~90%

- better thermal insulation properties

- higher temperature/fire resistance

- providing a viable use for ‘waste’ materials which are often disposed in landfill

Materials used in geopolymer concrete

A wide range of waste materials can

Examples of geopolymer concrete